There really doesn’t need to be two parts to this, but the second one will simply show all of the brakes done and some photos of the car in its final state, as I’m selling it, after a couple of enjoyable years of ownership.

The Paceman now has 36,000 miles on it, and while I’m not sure what the life of a set of brakes is, that strikes me as not as many miles as I’d expect–though far, far ahead of the Jaguar XJ6, which needs brakes every 1000 miles (!), so it seems.

The Mini brake parts were bought by the new owner, and I agreed to install them. I think all-in, with shipping and tax, they were just shy of $300 for four new rotors and the pads to go with them.

I’m only showing the swap of the right front corner here…I have yet to do the rest, which means I haven’t encountered the wear sensors that are on the left side. Apparently they can be a bit tricky to salvage… guess we’ll find out. (The wheels were on like the hubs of hell, BTW–the bolts were really tight. That was fun!)

Above is the start of the job…but the photo is after a preliminary scrub of the wheel well. Most of the time I have in this job is cleaning stuff–you could do a corner in 15 minutes, instead of two or three hours, if you don’t mind the mess; it wouldn’t affect how well the brakes work.

The rotors have a visible ridge where the pads ride, outside and inside, roughly the depth of a dime–they have worn to the point where surfacing them is a waste, and my experience has been that’s mroe money than new in any case.

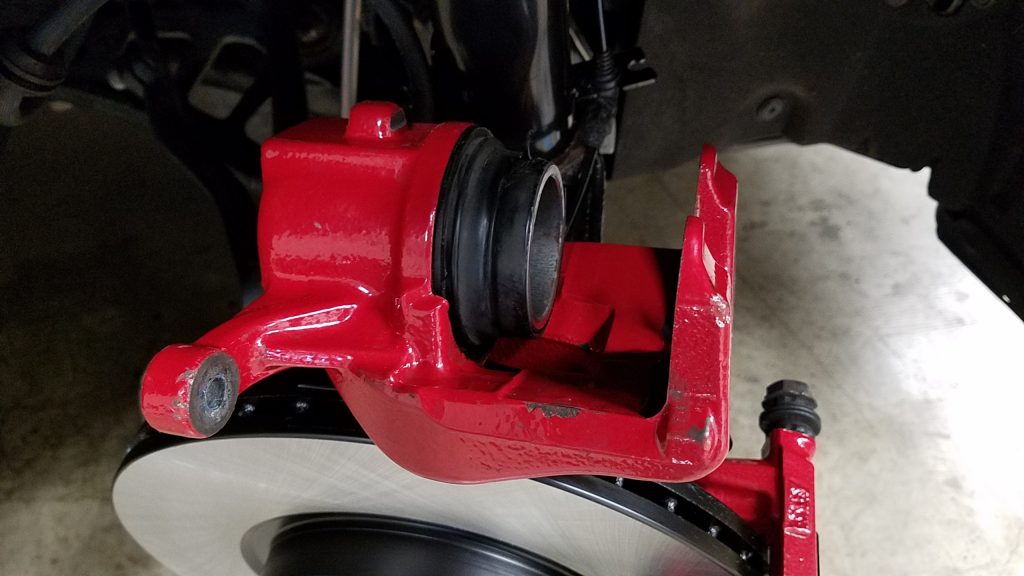

Here the floating part of the caliper has been taken off the caliper frame and tied out of the way…I later discovered the brake hose is long enough to allow the caliper to sit on the floor without stressing the it. The caliper was attached with a couple of 13mm bolts, and they came off easily enough.

Here’s the frame detached, the rotor removed, and the bits being reused mostly cleaned up. The frame is held onto the suspension upright with two 16mm bolts, and the rotor is held on with a single 6mm socket bolt. Again, that brake caliper will sit happily on the floor, but I had not discovered that yet. As Sansa said to Littlefinger: “it’s true, I’m a slow learner: but I learn”. The first bit is true about me, anyway…

Here are the new bits, ready to go on. Rotors look good, the last set I put on the XJ6 were not this nice. The JCW uses 307mm front rotors, most of the rest of the Countryman/Pacemans had 280mm, I believe.

Rotor and caliper frame back on…

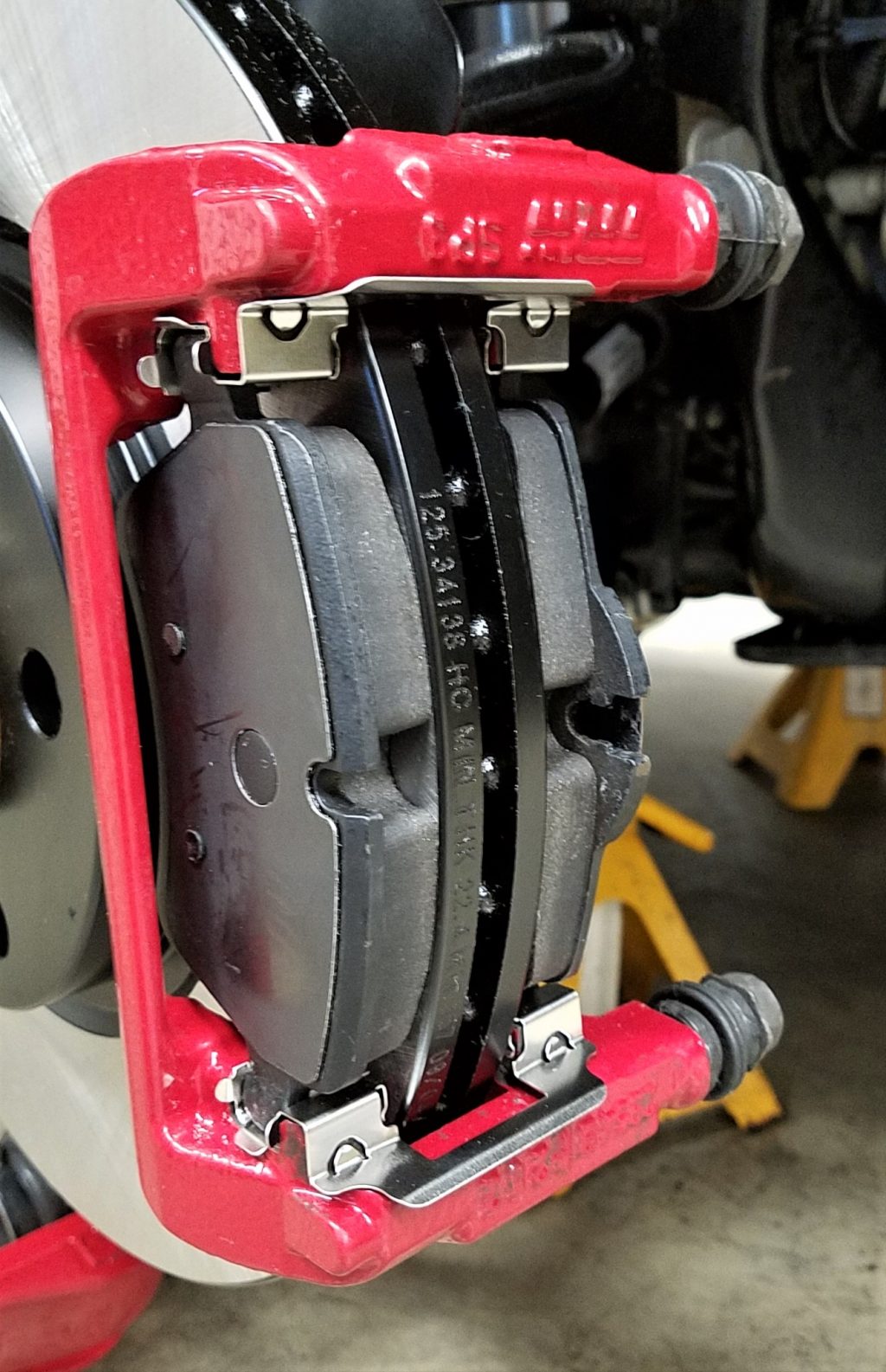

New pads and shims in place. I’ll show a comparison between the thickness of the old and new below.

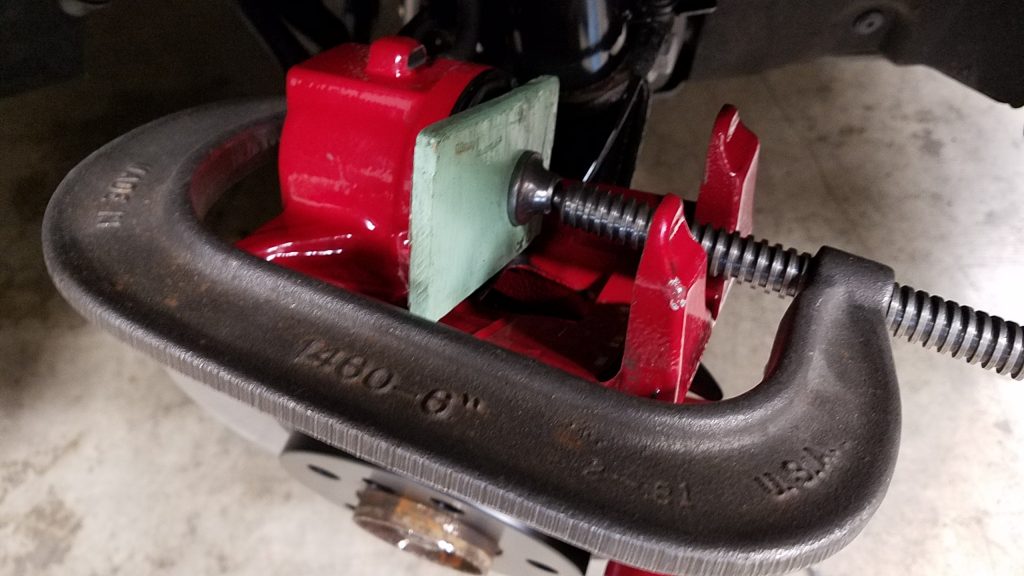

The hydraulic piston needs to be retracted into the floating part of the caliper so that it can fit around the new pads. This is easily accomplished with a scrap of wood and a C-Clamp:

Excuse the craptastic photos, BTW. This phone is due for replacement, I think…every time I buy a phone, I try to buy the one with the best camera quality, and every time I’m disappointed. Sigh. Anyway.

And here’s the final result. The photo at page top also shows this.

Above is the difference betwixt old and new pad thicknesses. I would guess the rotor wore at roughly the same rate–not in actual mm disappeared, so to speak, but rather comparing the original starting thickness to a “it’s worn out” thickness.

Anyway, one down, three to go. 45 minutes of actual brake work left, and a number of hours of cleaning. I’ll post the final results when I’m done, so y’all have that excitement to look forward to.