Sorry to have been absent for such a long time, but I did almost nothing on my own projects this past year, instead helping an E-Type owner reassemble his 4.2 fixed-head coupe, as seen above. We’re not quite done yet, but hopefully another month or so will see it drive away under its own power.

The car arrived as a bare, painted shell, more-or-less. A few things had been installed, as seen above, but I had to put the puzzle together. Sadly, most of the original nuts and bolts had been misplaced, so we had to use new throughout.

This started with putting the brand-new framework in place (which had not been fit before painting–we got lucky in that it went right on, unlike the struggle on my own car a decade ago).

Adjustable reaction plate and other gubbons slowly going in. Not a huge fan of adjustable reaction plates, they seem more trouble than they are worth, but I’m pretty old-school (actually, I’m just pretty old!).

Front suspension and brakes, minus the shocks and torsion bars at this juncture. Brakes are upgraded vented units; look good quality but the standard brakes work pretty well for road use, too.

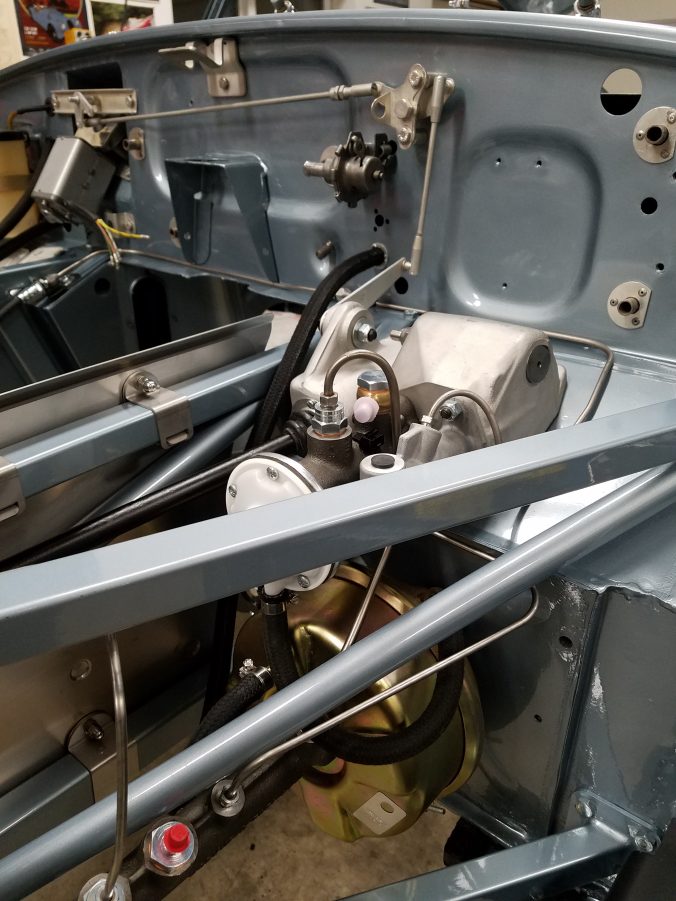

Pedal box, servo and brake piping went in. Brake piping kit was provided with car and was at best “approximate”, necessitating a couple of hand-bent replacement pipes. You can also see a custom “upgraded” heat shield, not my favorite bit of kit, but it proved to be OK at end of day.

The rear axle had been rebuilt previously, and it made it into the car, not without a struggle, not sure why. Warm butter, various ropes and the help of a donkey saw the job complete.

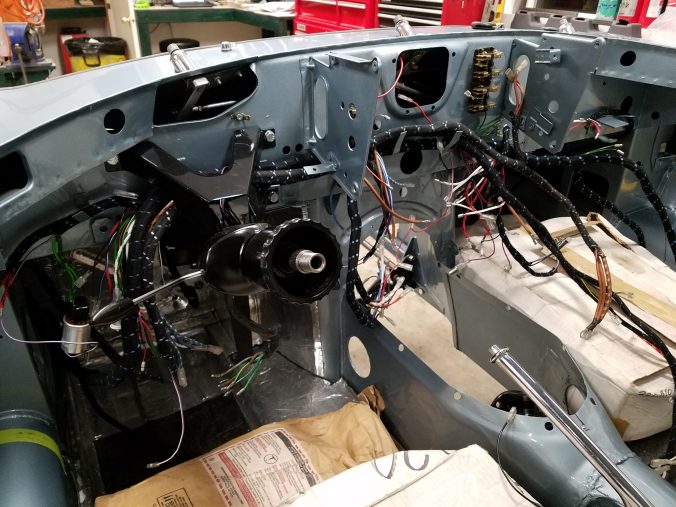

Wiring had to go in…this harness set was new but slightly wrong for this particular car, but got there in the end after much cursing. Everything involves cursing, of course.

Just about ready for the engine to go back in…spent a fair while waiting for it to get back from machine shop. I used a small power supply to test electrical system as things got wired up.

I put the engine in from the bottom, which I had never done before. Advantage is slightly less fuss and slightly less chance to damage the paint; disadvantage is reaction plate and torsion bars have to be out, which you can get away with not doing from above if you take the top cover off gearbox.

Clearances are still very tight!

But you get there in the end.

Which is where we are now. (The owner took away the valve covers to polish them and I put on my spare set, from a 1968 car, for now.) Interior needs to go in, glass too, and the bonnet needs to be delivered. We got rid of the too-wide worn-out tires and got a set of proper tires as seen here.

Anyway, hopefully getting close to seeing this car back on the road. If you want me to general-contract your resto, I’d consider it, work has otherwise been slow. If you want a Morgan body constructed for your Moggie, I’d definitely be happy to build you one for a fair price. I enjoyed that project a lot.